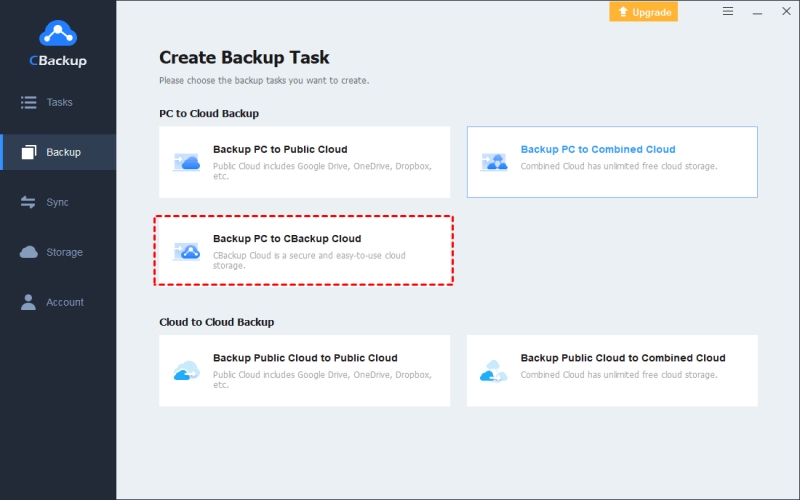

Free Online Backup Software: Backup Your Files Online Easily

Should I Use Online Backup? While data security is more important than ever, many individuals and organizations still don't have a comprehensive data backup and recovery strategy. This could be a... Read More »

Do You Want to Be a More Likeable Person?

Being likeable is a good thing! It means you're easy to get along with, pleasant to be around, and generally well-received by other people. It usually involves things like friendliness,... Read More »

Salesforce CPQ: Transforming the Sales Landscape

Have you ever wondered how businesses manage to customize, price, and quote their vast array of products and services so effectively? The answer lies in a tool called CPQ and one of the most powerful... Read More »

2How These Actors Balance...

Balancing work and family is a challenge for many, especially for actors whose jobs... Read More »

Why You Should Not Ignore...

Public relations (PR) is important to every business – big or small. If you... Read More »